- Home

- Standards

Standards

Piping and Flange Standards: Specifications | Types | FAQ

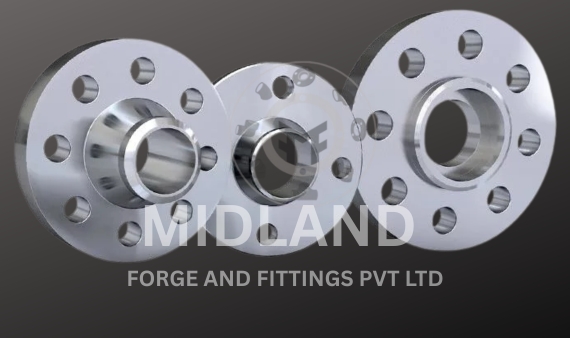

Global leader in piping and flange standards including ASME B16.5/B16.47 Flanges, ASME B16.9 Buttweld & B16.11 Forged Fittings, MSS SP-43/SP-75 Fittings, DIN, EN, GOST, JIS Flanges, and API 6A/605 Wellhead Flanges. Available in Carbon, Stainless, Alloy, Super Duplex Steel, and High Nickel Alloys – sizes ½” to 60” and pressure classes 150# to 2500#. Supplied worldwide, ensuring quality, safety, and international standards compliance.

Best Export Prices: sales@midlandforgefittings.com

We are a leading provider of globally recognized piping and flange standards, including ASME, MSS, DIN, EN, GOST, JIS, and API. Our standards-compliant products cover flanges, buttweld fittings, forged fittings, and elbows designed for high-pressure, high-temperature, and corrosive environments. With decades of experience, we ensure reliability, safety, and adherence to international industrial standards.

Our products are available in Carbon, Stainless, Alloy Steel, Super Duplex, and High Nickel Alloys, catering to diverse industrial applications. We offer sizes from ½” to 60” and pressure classes from 150# to 2500#, making it easy for engineers and procurement professionals to select the right components for any project. Every product is manufactured to meet global quality and performance standards.

Our piping and flange standards define precise dimensional tolerances, pressure ratings, wall thicknesses, hub designs, and material specifications to ensure reliable performance under varying operating conditions. They provide clear guidelines for branch-to-run ratios, stress distribution, weld integrity, and flow optimization, allowing engineers to design and fabricate piping systems that meet stringent ASME, MSS, DIN, EN, GOST, JIS, and API compliance requirements.

We supply standards-compliant piping and flange products worldwide to Europe, Africa, Asia, and Gulf countries. Our offerings serve multiple industries including oil & gas, petrochemical, power plants, water treatment, and industrial pipelines. By choosing our products, clients benefit from precision engineering, certified materials, and compliance with international standards, ensuring safe and efficient pipeline systems.

Piping and Flange Specifications

Standard Name / Reference

Pressure Classes / Ratings

Marking

Design Considerations

Scope

Flange / Connection Types

Test Certificates

Nominal Sizes

Testing / Inspection

Compliance / Certification

Production technique

Explore All Standards

- Standards

- ASME B16.5 Flanges

- ASME B16.47 Large Diameter Flanges

- ASME B16.9 Buttweld Fittings

- ASME B16.11 Forged Fittings

- ASME B16.28 Wrought Steel Elbows

- MSS SP-43 Stainless Steel Buttweld Fittings

- MSS SP-75 High Strength Butt Weld Fittings

- DIN Flanges

- EN Flanges

- GOST Flanges

- JIS Flanges

- MSS SP-95 – Swage Nipples & Bull Plugs

- MSS SP-97 – Integrally Reinforced Branch Outlets

- API 6A – Wellhead Flanges & Equipment

- API 605 – Large Diameter Flanges (replaced by ASME B16.47)

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Standards We Offer

International Flange Standards

What are the most commonly used standards for flanges and fittings?

- ASME B16.5 – Covers pipe flanges and flanged fittings from ½” to 24” NPS, pressure classes 150–2500#. Used widely in petrochemical, power, and water systems.

- ASME B16.47 – Large diameter flanges beyond 24” NPS, suitable for high-capacity pipelines.

- ASME B16.9 – Butt-weld fittings for piping systems; includes elbows, tees, reducers, caps.

- ASME B16.11 – Forged fittings for high-pressure systems, threaded or socket weld types.

- ASME B16.28 – Wrought steel elbows, ensuring precise bend radii and wall thicknesses for process piping.

- MSS SP-43 / SP-75 – Stainless steel and high-strength butt weld fittings with detailed dimensional tolerances.

- DIN / EN / GOST / JIS – European, Russian, and Japanese standards, ensuring global compatibility.

- MSS SP-95 / SP-97 – Swage nipples, bull plugs, and integrally reinforced branch outlets.

- API 6A / API 605 – Wellhead flanges and large-diameter flanges for oil & gas applications.

What is the difference between ASME, MSS, DIN, EN, GOST, and JIS standards?

- ASME (American Society of Mechanical Engineers): Primarily used in the US and globally for pressure piping, flanges, and fittings. Focuses on dimensional uniformity and pressure-temperature ratings.

- MSS (Manufacturers Standardization Society): Focused on wrought, forged, and high-strength fittings. Often supplements ASME standards with detailed tolerances.

- DIN / EN (German / European Standards): Metric-based; widely used in Europe. Specifies dimensions, material grades, and pressure classes.

- GOST (Russian Standards): Applicable in Russia and CIS countries; ensures compatibility in local industrial systems.

- JIS (Japanese Industrial Standards): Metric-based, mostly used in Japan and some Asian countries; similar in scope to DIN/EN but with local material grades.

How to select materials according to these standards?

- Selection is based on corrosion resistance, temperature, pressure, and media compatibility.

-

Common materials include:

- Carbon Steel (A105, A350 LF2): General purpose for water, oil, steam.

- Alloy Steel (F11, F22): High-temperature, high-pressure applications.

- Stainless Steel (F304, F316, F316L): Corrosive or chemical environments.

- Nickel & Copper Alloys: Offshore, marine, and high-temperature chemical systems.

- Duplex / Super Duplex SS: Highly corrosive and high-pressure pipelines.

- Standards like ASME B16.5 and MSS SP-43 provide specific recommended grades.