- Home

- Outlet Fittings

Outlet Fittings

Outlet Fittings: Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

ASME B16.11 / MSS-SP-97 Outlet Fittings – Leading Manufacturer & Exporter of Forged Branch Connections (Weldolet, Sockolet, Threadolet, Elbolet, Latrolet & Nipolet) in CS, SS, Alloy Steel & Duplex – Sizes ½” to 24”, Run Pipe up to 72”, Pressure Classes 3000#, 6000#, 9000# – Supplied to Europe, Africa, Asia & Gulf Countries

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a trusted manufacturer, supplier, and exporter of high-quality Outlet Fittings designed for reliable branch connections in piping systems. With decades of experience in the forging industry. we combine advanced manufacturing techniques with strict quality control to ensure every fitting meets international standards.

We specialize in producing Weldolet, Sockolet, Threadolet, Elbolet, Latrolet, and Nipolet as per ASME B16.11 and MSS-SP-97 standards. Our fittings are engineered to deliver excellent strength, leak-proof performance, and durability in demanding industrial applications.

Outlet fittings, also known as branch connection fittings, are specialized forged pipe fittings designed to provide an integral and reliable outlet from a larger pipe to a smaller one without the need for reducing tees or boring holes. Outlet fittings are widely used in high-pressure, high-temperature, and critical piping systems across industries like oil & gas, petrochemicals, refineries, power plants, shipbuilding, and chemical processing.

Olet fittings provide reinforced branch connections that ensure structural integrity, leak-proof performance, and cost efficiency by eliminating bulky tees and extra welds. They are versatile, available in socket weld, threaded, and butt weld ends with pressure classes 3000#, 6000#, and 9000#, and their compact design allows smooth flow with minimal pressure drop. This makes them ideal for critical pipelines, delivering long service life, reduced maintenance, and reliable performance across industries.

As a globally recognized company, Midland Forge, exports outlet fittings to clients in the USA, Germany, UK, Australia, Middle East, Africa, and Asia. With a strong focus on customer satisfaction, timely delivery, and competitive pricing, we have established ourselves as a reliable partner for industries worldwide. Our commitment to quality, innovation, and consistency makes us one of the leading names in Outlet Fittings manufacturing.

Outlet Fittings Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Industrial Outlet Fittings – Materials, Grades & Standards

| Material Category | Standards, Grade (ASTM / ASME) | Recommended Fitting Types | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Weldolet, Sockolet, Threadolet, Nipolet | 3000#–9000#, ½”–24” |

General purpose, corrosion resistance |

| ASTM A182 F316 / F316L / F316H | Weldolet, Sockolet, Threadolet, Nipolet | 3000#–9000#, ½”–24” |

Marine, chemical, and food processing | |

| ASTM A182 F321 / F321H | Weldolet, Sockolet | 3000#–9000#, ½”–24” |

High temperature, stabilized service | |

| Carbon Steel | ASTM A105 | Weldolet, Sockolet, Threadolet | 3000#–9000#, ½”–24” |

Pressure piping & general industries |

| ASTM A350 LF2 | Weldolet, Sockolet | 3000#–9000#, ½”–24” |

Low temperature services | |

| Alloy Steel | ASTM A182 F11 / F22 | Weldolet, Sockolet, Threadolet | 3000#–9000#, ½”–24” |

Steam lines & refineries |

| ASTM A182 F91 | Weldolet, Sockolet | 3000#–9000#, ½”–24” |

Power generation, high-performance pipelines |

|

| Duplex / Super Duplex Steel | ASTM A182 F51 / F53 / F55 / F60, UNS S31803 / S32205 / S32750 / S32760 |

Weldolet, Sockolet | 3000#–9000#, ½”–24” |

Corrosion resistance, offshore, seawater applications |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Weldolet, Sockolet, Threadolet | 3000#–9000#, ½”–24” |

Heat exchangers, aerospace, chemical processing |

| ASTM B564 Monel 400 / K500 | Weldolet, Sockolet | 3000#–9000#, ½”–24” |

Seawater, marine engineering | |

| Copper Nickel | ASTM B151 / B467 Cu-Ni 90/10 / 70/30 |

Weldolet, Sockolet | 3000#–9000#, ½”–24” |

Marine systems, seawater service |

| Titanium | ASTM B381 Grade 2 / Grade 5 | Weldolet, Sockolet | 3000#–9000#, ½”–24” |

Lightweight, corrosion resistance |

| Aluminium | ASTM B247 6061 / 5083 | Weldolet | 2000#–6000#, ½”–12” |

Low-pressure, non-corrosive piping |

Explore Outlet Fittings

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Types of ASME B16.11 Outlet Fittings

Dimensions of ASME B16.11 Weldolet - MSS SP97

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1/2 | 3/4 19.05 | 1.3/8 34.93 | 15/16 23.81 | 5/8 15.88 |

| 3/4 | 7/8 22.23 | 1.5/8 41.28 | 1.3/16 30.16 | 13/16 20.64 |

| 1 | 1.1/16 26.99 | 2 50.80 | 1.7/16 36.51 | 1.1/32 26.19 |

| 1.1/4 | 1.1/4 31.75 | 2.3/8 60.3 | 1.3/4 44.45 | 1.3/8 34.93 |

| 1.1/2 | 1.5/16 33.34 | 2.7/8 73 | 2 50.80 | 1.5/8 41.28 |

| 2 | 1.1/2 38.10 | 3.1/2 88.90 | 2.9/16 65.09 | 2.1/16 52.39 |

| 2.1/2 | 1.5/8 41.28 | 4.1/16 103.19 | 3 76.20 | 2.7/16 61.91 |

| 3 | 1.3/4 44.45 | 4.13/16 122.24 | 3.11/16 93.66 | 3.1/16 77.79 |

| 3.1/2 | 2 50.80 | 5.3/8 136.53 | 3.7/8 98.43 | 3.9/16 90.49 |

| 4 | 2 50.80 | 6 152.40 | 4.3/4 120.65 | 4 101.60 |

| 5 | 2.1/4 57.15 | 7.1/8 180.98 | 5.9/16 141.29 | 5.1/16 128.59 |

| 6 | 2.3/8 60.3 | 8.1/2 215.90 | 6.11/16 169.86 | 6.1/16 153.99 |

| 8 | 2.3/4 69.85 | 10.3/8 263.53 | 8.11/16 220.66 | 7.15/16 201.61 |

| 10 | 3.1/16 77.79 | 12.9/16 319.09 | 10.13/16 274.64 | 10 254.00 |

| 12 | 3.3/8 85.73 | 14.7/8 377.83 | 12.13/16 325.44 | 12 304.80 |

| 14 | 3.1/2 88.90 | 16.1/8 409.58 | 14.1/16 357.19 | 13.1/4 336.55 |

| 16 | 3.11/16 93.66 | 18¼ 463.55 | 16.1/16 407.99 | 15¼ 387.35 |

| 18 | 4.1/16 103.19 | 20.3/4 527.05 | 18.5/8 473.08 | 17¼ 438.15 |

| 20 | 4.5/8 117.48 | 23.1/16 585.79 | 20.1/16 509.59 | 19¼ 488.95 |

| 24 | 5.3/8 136.53 | 27.7/8 708.03 | 25.1/8 638.18 | 23.1/4 590.55 |

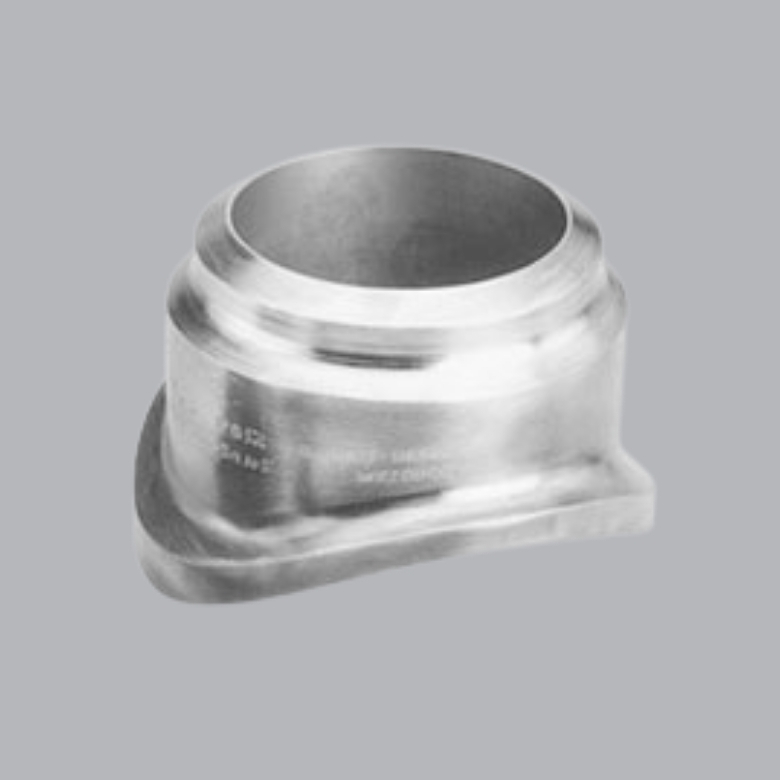

Dimensions of ASME B16.11 Sockolets - MSS SP97 (Class 3000)

| NPS | A | B | C | D | E |

|---|---|---|---|---|---|

| 1/2 | 1 25.4 |

1.3/8 34.92 |

15/16 23.81 |

0.622 15.80 |

17/32 13.49 |

| 3/4 | 1.1/16 26.98 |

1.5/8 41.27 |

1.3/16 30.16 |

0.824 20.93 |

15/32 11.90 |

| 1 | 1.5/16 33.33 |

2 50.8 |

1.7/16 36.51 |

1.049 26.64 |

23/32 18.25 |

| 1.1/4 | 1.5/16 33.33 |

2.3/8 60.32 |

1.3/4 44.45 |

1.380 35.05 |

9/16 14.28 |

| 1.1/2 | 1.3/8 34.92 |

2.7/8 73.02 |

2 50.8 |

1.610 40.89 |

21/32 16.66 |

| 2 | 1.1/2 38.1 |

3.1/2 88.9 |

2.9/16 65.08 |

2.067 52.50 |

15/16 23.81 |

| 2.1/2 | 1.9/16 39.68 |

4.1/16 103.18 |

3 76.2 |

2.469 62.71 |

3/4 19.05 |

| 3 | 1.3/4 44.45 |

4.13/16 122.23 |

3.11/16 93.66 |

3.068 77.93 |

15/16 23.81 |

| 3.1/2 | 1.11/16 42.86 |

5.3/8 136.52 |

4.7/16 112.71 |

3.548 90.12 |

11/16 17.46 |

| 4 | 1.7/8 47.62 |

6.1/16 153.98 |

4.3/4 120.65 |

4.026 102.26 |

1.1/16 26.98 |

| 5 | 2.7/16 61.91 |

7¼ 184.15 |

5¼ 133.35 |

5.047 128.19 |

1 25.4 |

| 6 | 2.11/16 68.26 |

8.11/16 220.66 |

6.1/16 153.98 |

6.065 154.05 |

1.3/16 30.16 |

| X = Min. 1/16 (1.6 mm) | |||||

Dimensions of ASME B16.11 Thredolets - MSS SP97 (Class 3000)

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1/2 | 1 25.40 | 1.3/8 34.92 | 15/16 23.81 | 5/8 15.87 |

| 3/4 | 1.1/16 26.98 | 1.5/8 41.27 | 1.3/16 30.16 | 13/16 20.63 |

| 1 | 1.5/16 33.33 | 2 50.80 | 1.7/16 36.51 | 1.1/16 26.98 |

| 1.1/4 | 1.5/16 33.33 | 2.3/8 60.32 | 1.3/4 44.45 | 1.3/8 34.92 |

| 1.1/2 | 1.3/8 34.92 | 2.7/8 73.02 | 2 50.80 | 1.5/8 41.27 |

| 2 | 1.1/2 38.10 | 3.1/2 88.90 | 2.9/16 65.08 | 2.1/16 52.38 |

| 2.1/2 | 1.29/32 48.41 | 4.1/16 103.18 | 3 76.20 | 2.1/2 63.50 |

| 3 | 2 50.80 | 4.13/16 122.23 | 3.11/16 93.66 | 3.1/16 77.78 |

| 3.1/2 | 2.1/8 53.97 | 5.3/8 136.52 | 4.7/16 112.71 | 3.9/16 90.48 |

| 4 | 2.1/4 57.15 | 6.1/16 153.98 | 4.3/4 120.65 | 4.1/16 103.18 |

| 5 | 2.7/16 61.91 | 7¼ 184.15 | 5¼ 133.35 | 5¼ 133.35 |

| 6 | 2.3/4 69.85 | 8.11/16 220.66 | 5.3/4 146.05 | 5.3/4 146.05 |

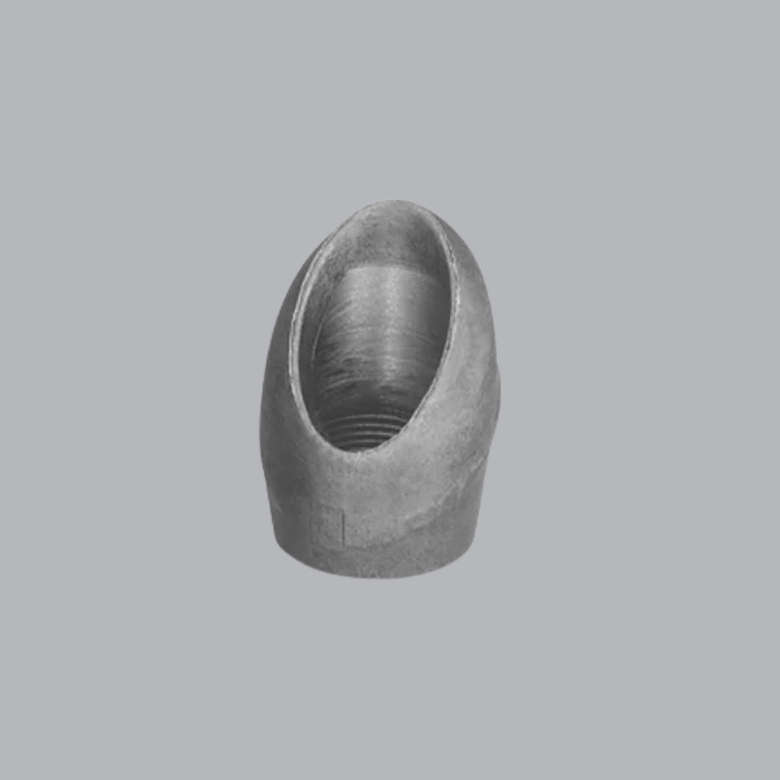

Dimensions of ASME B16.11 Elbolet - MSS SP97 (Class 3000, 6000)

| Nominal Elbow Size (NPS) | Outlet Size (NPS) | CL 3000 | CL 6000 | ||

|---|---|---|---|---|---|

| C | E | C | E | ||

| 36 – 3/4 | 1/4 | 38.10 | 40.48 | 38.10 | 40.48 |

| 36 – 3/4 | 3/8 | 38.10 | 40.48 | 38.10 | 40.48 |

| 36 – 3/4 | 1/2 | 38.10 | 40.48 | 43.65 | 47.63 |

| 36 – 1 | 3/4 | 43.65 | 47.63 | 57.15 | 57.15 |

| 36 – 2 | 1 | 57.15 | 57.15 | 73.03 | 63.50 |

| 36 – 2 | 1.1/4 | 73.03 | 63.50 | 79.38 | 68.26 |

| 36 – 2 | 1.1/2 | 79.38 | 68.26 | 106.36 | 82.55 |

| 36 – 3 | 2 | 106.36 | 95.25 | – | – |

Dimensions of ASME B16.11 Latrolet - MSS SP97 (Class 3000, 6000)

| STD & XS Butt Weld | ||||

|---|---|---|---|---|

| NPS | A | B | C | E |

| 1/4 | 33.34 | 53.18 | 36.51 | 39.69 |

| 3/8 | 33.34 | 53.18 | 36.51 | 39.69 |

| 1/2 | 34.93 | 54.77 | 36.51 | 39.69 |

| 3/4 | 42.86 | 64.29 | 44.45 | 48.42 |

| 1 | 50.01 | 76.20 | 53.98 | 55.56 |

| 1.1/4 | 57.94 | 91.28 | 66.68 | 62.71 |

| 1.1/2 | 62.71 | 100.81 | 76.99 | 66.68 |

| 2 | 80.96 | 133.35 | 104.78 | 86.52 |

| 2.1/2 | 80.17 | 131.76 | 104.78 | 80.17 |

| 3 | 96.84 | 158.75 | 126.21 | 96.04 |

| 4 | 120.65 | 198.44 | 163.51 | 115.89 |

| Sch.160 & XXS Butt Weld | |||

|---|---|---|---|

| NPS | A | B | C |

| 1/4 | 39.69 | 58.74 | 36.51 |

| 3/8 | 39.69 | 58.74 | 36.51 |

| 1/2 | 46.04 | 69.85 | 44.45 |

| 3/4 | 53.98 | 82.55 | 53.98 |

| 1 | 63.50 | 96.84 | 66.68 |

| 1.1/4 | 69.85 | 107.95 | 76.20 |

| 1.1/2 | 85.73 | 136.53 | 104.78 |

| 2 | 80.96 | 133.35 | 104.78 |

| 2.1/2 | 80.17 | 131.76 | 104.78 |

| 3 | 96.84 | 158.75 | 126.21 |

| 4 | 120.65 | 198.44 | 163.51 |

| Class 3000 Threaded & Socket Weld | ||||

|---|---|---|---|---|

| NPS | A | B | C | E |

| 1/4 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/8 | 39.69 | 59.53 | 36.51 | 39.69 |

| 1/2 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/4 | 47.63 | 69.85 | 44.45 | 48.42 |

| 1 | 55.56 | 82.55 | 53.98 | 55.56 |

| 1.1/4 | 63.50 | 97.63 | 66.68 | 74.61 |

| 1.1/2 | 69.85 | 107.16 | 76.99 | 66.68 |

| 2 | 85.73 | 138.11 | 104.78 | 80.17 |

| Class 6000 Threaded & Socket Weld | ||||

|---|---|---|---|---|

| NPS | A | B | C | E |

| 1/4 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/8 | 39.69 | 59.53 | 36.51 | 39.69 |

| 1/2 | 47.63 | 69.85 | 44.45 | 48.42 |

| 3/4 | 55.56 | 82.55 | 53.98 | 55.56 |

| 1 | 63.50 | 92.87 | 66.68 | 62.71 |

| 1.1/4 | 69.85 | 107.16 | 76.99 | 66.68 |

| 1.1/2 | 85.73 | 138.11 | 104.78 | 80.17 |

| 2 | 85.73 | 138.11 | 104.78 | 80.17 |

Weight Chart (lbs) : Pipe Branch Fittings (Carbon Steel Outlet Fittings)

| Fitting Type | Run Pipe Size (NPS) | Branch Size (NPS) | Weight (lbs) |

|---|---|---|---|

| Weldolet | ½” | ½” | 0.35 |

| 1″ | 1″ | 0.75 | |

| 2″ | 2″ | 1.90 | |

| 4″ | 4″ | 6.50 | |

| 6″ | 6″ | 14.0 | |

| Sockolet | ½” | ½” | 0.40 |

| 1″ | 1″ | 0.85 | |

| 2″ | 2″ | 2.00 | |

| 4″ | 4″ | 6.80 | |

| 6″ | 6″ | 14.5 | |

| Threadolet | ½” | ½” | 0.30 |

| 1″ | 1″ | 0.65 | |

| 2″ | 2″ | 1.50 | |

| 4″ | 4″ | 5.50 | |

| Elbolet | 2″ | 2″ | 1.60 |

| 4″ | 4″ | 5.80 | |

| Latrolet | 2″ | 2″ | 1.55 |

| 4″ | 4″ | 5.60 | |

| Nipolet | 1″ | 1″ | 0.50 |

| 2″ | 2″ | 1.40 | |

| 4″ | 4″ | 5.00 |

Olet Fitting Tolerances as per ASME B16.11

| Fitting Type | Run / Branch Size (NPS / DN) |

Socket Bore (B) Tolerance |

OD Tolerance | Height / Length (H/L) | Thread / Socket Depth |

|---|---|---|---|---|---|

| Weldolet | ½” – 24″ (DN15 – DN600) |

±0.5% of branch OD | ±0.5% of run OD | ±1/16″ (≤6″) / ±1/8″ (>6″) | Socket depth ±1/16″ |

| Sockolet | ½” – 24″ (DN15 – DN600) |

±0.5% of branch OD | ±0.5% of run OD | ±1/16″ (≤6″) / ±1/8″ (>6″) | Socket depth ±1/16″ |

| Threadolet | ½” – 24″ (DN15 – DN600) |

±0.5% of branch OD | ±0.5% of run OD | ±1/16″ (≤6″) / ±1/8″ (>6″) | Thread per ANSI B1.20.1 |

| Elbolet | ½” – 24″ (DN15 – DN600) |

±0.5% of branch OD | ±0.5% of run OD | ±1/16″ (≤6″) / ±1/8″ (>6″) | Socket depth ±1/16″ |

| Latrolet | ½” – 24″ (DN15 – DN600) |

±0.5% of branch OD | ±0.5% of run OD | ±1/16″ (≤6″) / ±1/8″ (>6″) | Socket depth ±1/16″ |

| Nipolet | ½” – 24″ (DN15 – DN600) |

±0.5% of branch OD | ±0.5% of run OD | ±1/16″ (≤6″) / ±1/8″ (>6″) | Socket depth ±1/16″ |

How are Olet fittings classified based on connection type?

-

Welded Olets:

-

Weldolet → Butt-weld end, ideal for high-pressure pipelines.

-

Sockolet → Socket-weld end, mostly for smaller bore branch connections.

-

Elbolet → Designed for 90°/45° elbows, enabling branch connections at bends.

-

-

Threaded Olets:

-

Threadolet → Internal threaded branch for quick connection without welding.

-

-

Special Olets:

-

Latrolet (45° branch), Sweepolet (low-stress design), Nipolet (Olet + nipple combined).

✅ Classification helps engineers choose based on pressure, flow direction, and weldability.

-

Why are Olets preferred over traditional branch connections like T-joints?

-

Stress Distribution – Olets minimize stress concentration at the header-to-branch intersection, unlike T-joints that create weak zones.

-

Material Optimization – Requires less welding material compared to fabricated tees.

-

Flexibility – Olets can be used on straight pipes, elbows, or even reducers, whereas T-joints are limited.

-

Range of Sizes – Easily connects large headers to very small bore branches.

How does branch reinforcement work in Olet fittings?

-

Integral Reinforcement: Olets provide their own reinforcement without requiring pads.

-

Area Replacement Method: Metal removed from header during branch opening is compensated by extra thickness of Olet body.

-

Advantage: Simplifies fabrication and reduces additional weld pads, saving time.