- Home

- Forged Fittings

- Street Elbow

Street Elbow

Street Elbow : Specifications | Materials | Dimensions | Weight Chart | Tolerances | FAQ

Leading Exporter & Stockist of ASME B16.11 Forged 45° & 90° Street Elbows – Sizes ½” to 4”, Class 2000#, 3000#, 6000#, 9000#, available in Stainless Steel, Carbon Steel, Alloy Steel, and High Nickel Alloys, Exporting to USA, Germany, Australia, UAE, and South Africa

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a trusted manufacturer and global supplier of forged street elbow. With a strong focus on quality, precision, and reliability, the company follows international standards like ASME, ANSI, ASTM, and ISO to deliver superior products. Our customer-centric approach, state-of-the-art manufacturing facilities, and strict quality control systems have positioned us as a preferred partner for clients worldwide.

A street elbow is a type of pipe fitting designed to connect two pipes at an angle, with one end male-threaded and the other end female-threaded (or socket weld). Unlike a standard elbow, its integral male connection eliminates the need for a separate nipple, making installation quicker and more compact.

Street elbows are manufactured in stainless steel, carbon steel, alloy steel, and high nickel alloys, with pressure classes ranging from 2000# to 9000#, ensuring durability and leak-proof performance in demanding applications.

Street elbows are available in two main connection types: socket weld street elbows for high-pressure, permanent welded joints, and threaded street elbows for easy assembly and disassembly in piping systems. They are further classified by angle – 45° street elbows are used where a smooth directional change with minimal flow resistance is required, while 90° street elbows are ideal for sharp turns in compact piping layouts. Their versatility makes them suitable for high-pressure piping, hydraulic systems, steam lines, and chemical processing applications.

Forged 45° Street Elbow Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Threaded 90° Street Elbow – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

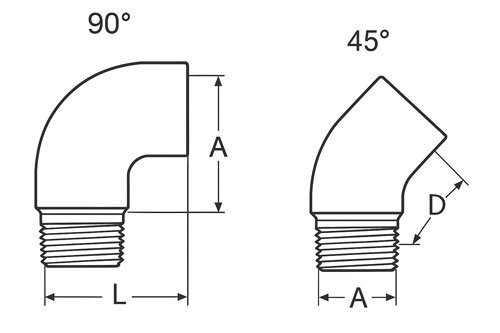

Dimensions of ASME B16.11 Street Elbow 90°

| Nominal Pipe Size (NPS) | 2000# (L) | 3000# (L) | 6000# (L) | Center to End (A) |

|---|---|---|---|---|

| 1/8″ | 19 | 22 | 25 | 19 |

| 1/4″ | 22 | 25 | 28 | 22 |

| 3/8″ | 25 | 28 | 30 | 25 |

| 1/2″ | 28 | 33 | 38 | 28 |

| 3/4″ | 33 | 38 | 44 | 33 |

| 1″ | 38 | 44 | 51 | 38 |

| 1-1/4″ | 44 | 51 | 57 | 44 |

| 1-1/2″ | 51 | 57 | 64 | 51 |

| 2″ | 60 | 64 | 83 | 60 |

| 2-1/2″ | 76 | 83 | 95 | 76 |

| 3″ | 83 | 95 | 106 | 83 |

| 4″ | 106 | 114 | 133 | 106 |

Dimensions of ASME B16.11 Street Elbow 45°

| Nominal Pipe Size (NPS) | 2000# (L) | 3000# (L) | 6000# (L) | Center to End (A) |

|---|---|---|---|---|

| 1/8″ | 16 | 19 | 22 | 16 |

| 1/4″ | 19 | 22 | 25 | 19 |

| 3/8″ | 22 | 25 | 28 | 22 |

| 1/2″ | 25 | 28 | 33 | 25 |

| 3/4″ | 28 | 33 | 38 | 28 |

| 1″ | 33 | 38 | 44 | 33 |

| 1-1/4″ | 38 | 44 | 51 | 38 |

| 1-1/2″ | 44 | 51 | 57 | 44 |

| 2″ | 51 | 57 | 64 | 51 |

| 2-1/2″ | 64 | 70 | 76 | 64 |

| 3″ | 70 | 76 | 83 | 70 |

| 4″ | 83 | 95 | 106 | 83 |

Weight Chart: ASME B16.11 Street Elbow – Socket Weld / Threaded

| Nominal Pipe Size (NPS) | 2000# (kg) | 3000# (kg) | 6000# (kg) |

|---|---|---|---|

| 1/8″ | 0.03 | 0.05 | 0.08 |

| 1/4″ | 0.05 | 0.08 | 0.12 |

| 3/8″ | 0.07 | 0.11 | 0.16 |

| 1/2″ | 0.11 | 0.16 | 0.23 |

| 3/4″ | 0.16 | 0.23 | 0.34 |

| 1″ | 0.23 | 0.34 | 0.50 |

| 1-1/4″ | 0.34 | 0.50 | 0.75 |

| 1-1/2″ | 0.50 | 0.75 | 1.10 |

| 2″ | 0.75 | 1.10 | 1.65 |

| 2-1/2″ | 1.10 | 1.65 | 2.45 |

| 3″ | 1.65 | 2.45 | 3.70 |

| 4″ | 2.80 | 4.20 | 6.40 |

ASME B16.11 Street Elbow – Tolerances

| Parameter | Tolerance | Applicable To |

|---|---|---|

| Socket Bore Diameter (B) | ±0.10 mm | Socket Weld |

| Socket Depth (J) | ±0.40 mm | Socket Weld |

| Thread Dimensions | As per ASME B1.20.1 (NPT), ±0.10 mm | Threaded |

| Thread Engagement Length | ±0.40 mm | Threaded |

| Center-to-End Dimension (A, L) | ±1.5 mm (NPS ≤ 1½”) ±3.0 mm (NPS 2″–4″) | Socket Weld & Threaded |

| Axial Alignment (Bore Concentricity) | ±1.0 mm | Socket Weld |

| Out-of-Squareness of Face | ≤ 0.06 mm per 25 mm dia | Socket Weld & Threaded |

| Angular Tolerance (90° Elbow) | ±1.5° | Socket Weld & Threaded |

| Angular Tolerance (45° Elbow) | ±1.0° | Socket Weld & Threaded |

| Wall Thickness | Minimum = 87.5% of nominal Maximum = not limited | Socket Weld & Threaded |

How to identify a Street Elbow vs. a Standard Elbow?

The key distinction lies in the end connections and the way each fitting is used:

-

Street Elbow

- Has one male end (spigot for socket weld or external thread for threaded type).

- Has one female end (socket for welding or internal thread for threaded type).

- Can connect directly to another fitting without requiring a nipple.

- Commonly used where fittings must join in limited space or when reducing the number of joints is preferred.

-

Standard Elbow

- Both ends are female (either both socket weld ends or both internally threaded ends).

- To connect a standard elbow to another fitting, a short nipple or extra pipe piece is required.

- Adds an extra joint, which can slightly increase the risk of leakage and requires more installation effort.

-

Practical Difference in Use

- Street Elbow → Provides direct connection, saves space, reduces fittings, and is ideal for compact or complex layouts.

- Standard Elbow → More common in general piping systems but may require additional fittings to complete a connection.

What are the advantages of using a Street Elbow?

Using an ASME B16.11 Street Elbow offers several practical and technical advantages in piping systems:

-

Space Saving

- Since a street elbow has one male (spigot/threaded) end and one female (socket/threaded) end, it can directly connect to another fitting.

- This eliminates the need for an additional short nipple between fittings.

- Particularly useful in tight or compact piping layouts where space is limited, such as skid-mounted units and marine pipelines.

-

Cost Effective

- By reducing the number of fittings (no nipple required), the overall material cost of the piping system decreases.

- Fewer fittings also mean reduced installation labor costs and a smaller inventory of spare parts.

-

Quick Installation

- Direct male-to-female connection simplifies assembly.

- Saves time during maintenance, repair, or shutdown activities.

- Often chosen for temporary setups or systems that require frequent disassembly.

-

Versatility in Connections

- Available in Socket Weld Street Elbows (used in high-pressure, leak-proof welded systems).

- Also available in Threaded Street Elbows (suitable for small-bore piping and quick connections without welding).

- This dual availability allows engineers to select the most appropriate type depending on service conditions and installation requirements.

-

Pressure Handling Capability

- Manufactured in Class 2000#, 3000#, and 6000# as per ASME B16.11.

- This ensures safe performance across low, medium, and high-pressure applications.

- Suitable for critical industries such as oil & gas, petrochemicals, and power plants.

What is the difference between 45° and 90° Street Elbows?

-

A 45° Street Elbow changes the direction of flow by 45°, providing a smoother transition with less turbulence and lower pressure drop. It is used in fluid systems requiring gradual directional change, such as cooling water lines or hydraulic systems.

-

A 90° Street Elbow changes the direction of flow by 90°, enabling a sharp turn within compact spaces. It is suitable for tight piping layouts, steam lines, and compressed air systems.