- Home

- Forged Fittings

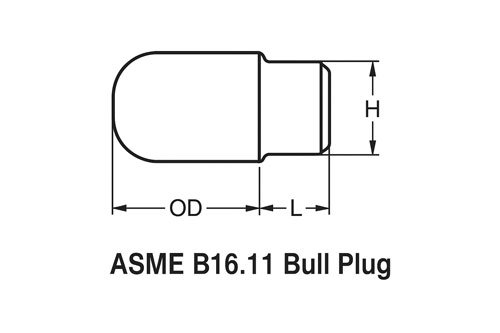

- Bull Plug

Bull Plug

Bull Plug : Specifications | Materials | Dimensions | Weight Chart | Tolerances | FAQ

Trusted Manufacturer & Supplier of ASME B16.11 Bull Plugs – Sizes ½” to 4”, Class 2000#, 3000#, 6000#, 9000#, available in Stainless Steel, Carbon Steel, Alloy Steel, and High Nickel Alloys, Exporting to UK, Italy, Canada, Saudi Arabia, and Singapore

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer and exporter of high-performance forged bull plug fittings, catering to diverse industries across the globe. With decades of experience and a strong focus on innovation, the company has built a reputation for delivering products that meet international standards such as ASME, ASTM, and ANSI. Backed by advanced manufacturing facilities and a dedicated workforce, Midland Forge, ensures superior quality, timely delivery, and customer-focused solutions for demanding industrial applications.

A bull plug is a forged pipe fitting used to close or seal the end of a piping line in high-pressure applications. It is essentially a solid plug with a male thread or weld end that fits securely into a female threaded or socket weld opening.

Designed in accordance with ASME B16.11 standards, bull plugs are available in pressure classes such as 2000#, 3000#, 6000#, and 9000#. The main advantage of a bull plug is its robust structure and leak-proof sealing capability, making it highly reliable for isolating sections of pipelines during maintenance, testing, or shutdown operations.

Midland Forge and Fittings Pvt. Ltd. places strong emphasis on quality control, with every bull plug undergoing stringent inspection and testing before dispatch. The company’s commitment to excellence has enabled it to supply forged fittings to key international markets including the UK, Italy, Canada, Saudi Arabia, and Singapore. By combining precision engineering, strict adherence to global standards, and a customer-first approach, Midland continues to be a trusted name for reliable ASME B16.11 Bull Plugs across industries worldwide.

Forged Bull Plug Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Threaded Bull Plug – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Dimensions of ASME B16.11 Bull Plug

| Nominal Pipe Size (NPS) |

Pressure Class | Outside Diameter (OD) (mm) |

Length (L) (mm) |

Socket Depth Thread Engagement (H) (mm) |

|---|---|---|---|---|

| ½” | 2000# – 9000# | 21.3 | 38 | 10 |

| ¾” | 2000# – 9000# | 26.7 | 44 | 13 |

| 1” | 2000# – 9000# | 33.4 | 51 | 13 |

| 1 ¼” | 2000# – 9000# | 42.2 | 57 | 14 |

| 1 ½” | 2000# – 9000# | 48.3 | 64 | 15 |

| 2” | 2000# – 9000# | 60.3 | 83 | 16 |

| 2 ½” | 2000# – 9000# | 73.0 | 89 | 19 |

| 3” | 2000# – 9000# | 88.9 | 95 | 20 |

| 4” | 2000# – 9000# | 114.3 | 105 | 22 |

Weight Chart: ASME B16.11 Bull Plug – Socket Weld / Threaded

| Nominal Pipe Size (NPS) | Bull Plug Type | Pressure Class | Approx. Weight (kg) |

|---|---|---|---|

| 1/8″ (DN6) | SW / THD | 3000# | 0.05 – 0.07 |

| 1/4″ (DN8) | SW / THD | 3000# | 0.08 – 0.10 |

| 3/8″ (DN10) | SW / THD | 3000# | 0.12 – 0.15 |

| 1/2″ (DN15) | SW / THD | 3000# / 6000# | 0.20 – 0.28 |

| 3/4″ (DN20) | SW / THD | 3000# / 6000# | 0.35 – 0.45 |

| 1″ (DN25) | SW / THD | 3000# / 6000# | 0.50 – 0.70 |

| 1 1/4″ (DN32) | SW / THD | 3000# / 6000# | 0.75 – 1.00 |

| 1 1/2″ (DN40) | SW / THD | 3000# / 6000# | 1.10 – 1.50 |

| 2″ (DN50) | SW / THD | 3000# / 6000# | 1.70 – 2.30 |

| 2 1/2″ (DN65) | SW / THD | 3000# / 6000# | 2.80 – 3.50 |

| 3″ (DN80) | SW / THD | 3000# / 6000# | 4.00 – 5.50 |

| 4″ (DN100) | SW / THD | 3000# / 6000# | 7.00 – 9.50 |

Socket Weld Bull Plug Tolerances as per ASME B16.11

| Parameter | Tolerance / Requirement |

|---|---|

| Outside Diameter (OD) | ±1% or ±0.5 mm (±0.02 in.), whichever is greater |

| Overall Length (L) | Up to NPS 1″ → ±1.5 mm (±0.06 in.) NPS 1¼”–2″ → ±3.0 mm (±0.12 in.) Above NPS 2″ → ±4.0 mm (±0.16 in.) |

| Wall Thickness (t) | Not less than 87.5% of nominal thickness (no upper limit if assembly not affected) |

| Socket Bore (B) | ±0.25 mm (±0.01 in.) |

| Socket Depth (H) | ±0.5 mm (±0.02 in.) |

| Threaded Bore | As per ASME B1.20.1 (NPT thread tolerances) |

| End Squareness (Socket Weld) | ±1° on squareness |

| Thread Engagement (THD type) | Within ±1 thread engagement length |

| Thread Form Finish | Clean, accurate, free from burrs or sharp edges |

How are ASME B16.11 Bull Plugs manufactured?

- Bull plugs are produced through hot forging or machining from forged bars/rounds, ensuring a homogeneous grain structure.

- After forging, they undergo heat treatment (normalizing, quenching, tempering) to achieve the required mechanical properties.

- Precision CNC machining is used for socket weld or threaded ends, ensuring compliance with ASME B16.11 and ASME B1.20.1 (NPT) standards.

- Each bull plug is subjected to dimensional inspection, hardness testing, and pressure testing to verify leak-proof performance.

What pressure classes are available for Bull Plugs as per ASME B16.11?

- Class 2000# – Suitable for standard pressure piping.

- Class 3000# – Commonly used in moderate pressure and high-temperature systems.

- Class 6000# – Designed for heavy-duty, high-pressure applications.

- Class 9000# – Specially used in extreme pressure conditions, mainly in oil & gas upstream and offshore installations.

Where are Bull Plugs typically used?

- Oil & Gas Pipelines: For closing unused headers and wellhead outlets.

- Petrochemical Plants: To isolate pipe sections during maintenance or modifications.

- Power Plants: In high-pressure steam, condensate, and feedwater lines.

- Marine & Offshore: To block ends of subsea pipelines and risers.

- Testing Applications: For hydrotesting, pneumatic testing, and system pressure integrity checks.