- Home

- Forged Fittings

- Socketweld & Threaded Cap

Socketweld & Threaded Cap

Forged Cap : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Manufacturer of ASME B16.11 Forged Caps – Socket Weld & Threaded Pipe End Caps | Sizes ½” to 4”, Class 3000# & 6000# | Stainless Steel, Carbon Steel, Alloy Steel & High Nickel Alloys | Export to USA, Germany, UAE, Australia & Africa

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer of forged Caps, delivering precision-engineered solutions for global piping industries. we focus on quality, reliability, and innovation. Our forged products are designed to meet international standards, ensuring durability and consistency in the most demanding environments.

We specialize in the manufacturing of ASME B16.11 Forged Caps in socket weld and threaded designs, available in sizes ½” to 4” and pressure classes 3000# and 6000#. Socketweld caps are used to securely seal the ends of pipes, offering a leak-proof closure that can withstand high-pressure and high-temperature conditions. threaded caps are widely applied in oil & gas, petrochemical, and power generation industries.

At Midland Forge, each forged cap undergoes strict quality checks to guarantee dimensional accuracy, corrosion resistance, and long service life. By combining advanced forging technology with rigorous inspection standards, we provide products that enhance operational safety and efficiency. Trusted by clients worldwide, we continue to export forged caps to major markets including the USA, Germany, UAE, Australia, and Africa, building long-term partnerships through reliability and performance.

Forged Cap Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Forged Threaded Cap – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Types of ASME B16.11 Forged Cap Fittings

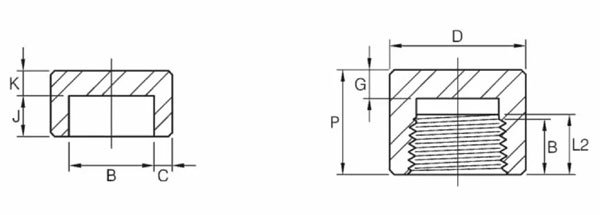

Dimensions of ASME B16.11 Socket Weld Cap

| DN | NPS | B (Min) | C (3000) | C (6000) | C (9000) | K (3000) | K (6000) | K (9000) | J (3000) | J (6000) | J (9000) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 1/8 | 10.8 | 3.18 | 3.96 | – | 3.18 | 3.43 | – | 4.8 | 6.4 | – |

| 8 | 1/4 | 14.2 | 3.30 | 4.60 | – | 3.30 | 4.01 | – | 4.8 | 6.4 | – |

| 10 | 3/8 | 17.6 | 4.01 | 5.03 | – | 3.50 | 4.37 | – | 4.8 | 6.4 | – |

| 15 | 1/2 | 21.8 | 4.67 | 5.97 | 9.35 | 4.09 | 5.18 | 8.18 | 6.4 | 7.9 | 11.2 |

| 20 | 3/4 | 27.2 | 4.90 | 6.96 | 9.78 | 4.27 | 6.04 | 8.56 | 6.4 | 7.9 | 12.7 |

| 25 | 1 | 33.9 | 5.69 | 7.92 | 11.38 | 4.98 | 6.93 | 9.96 | 9.6 | 11.2 | 14.2 |

| 32 | 1¼ | 42.7 | 6.07 | 7.92 | 12.14 | 5.28 | 6.93 | 10.62 | 9.6 | 11.2 | 14.2 |

| 40 | 1½ | 48.8 | 6.35 | 8.92 | 12.70 | 5.54 | 7.80 | 11.12 | 11.2 | 12.7 | 15.7 |

| 50 | 2 | 61.2 | 6.93 | 10.92 | 13.84 | 6.04 | 9.50 | 12.21 | 12.7 | 15.7 | 19.0 |

| 65 | 2½ | 73.9 | 8.76 | – | – | 7.67 | – | – | 15.7 | – | – |

| 80 | 3 | 89.8 | 9.52 | – | – | 8.30 | – | – | 19.0 | – | – |

| 100 | 4 | 115.2 | 10.69 | – | – | 9.35 | – | – | 22.4 | – | – |

Dimensions of ASME B16.11 Threaded Cap

| DN | NPS | B (Min) | L2 | P (3000) | P (6000) | D (3000) | D (6000) | G (3000) | G (6000) |

|---|---|---|---|---|---|---|---|---|---|

| 6 | 1/8 | 6.4 | 6.7 | 19 | – | 16 | – | 4.8 | – |

| 8 | 1/4 | 8.1 | 10.2 | 25 | 27 | 19 | 25 | 4.8 | 6.4 |

| 10 | 3/8 | 9.1 | 10.4 | 25 | 27 | 22 | 32 | 4.8 | 6.4 |

| 15 | 1/2 | 10.9 | 13.6 | 32 | 33 | 28 | 38 | 6.4 | 7.9 |

| 20 | 3/4 | 12.7 | 13.9 | 37 | 38 | 35 | 44 | 6.4 | 7.9 |

| 25 | 1 | 14.7 | 17.3 | 41 | 43 | 44 | 57 | 9.7 | 11.2 |

| 32 | 1¼ | 17.0 | 18.4 | 44 | 46 | 57 | 64 | 9.7 | 11.2 |

| 40 | 1½ | 17.8 | 18.4 | 44 | 48 | 64 | 76 | 11.2 | 12.7 |

| 50 | 2 | 19.0 | 19.2 | 48 | 51 | 76 | 92 | 12.7 | 15.7 |

| 65 | 2½ | 23.6 | 28.9 | 60 | 64 | 92 | 108 | 15.7 | 19.0 |

| 80 | 3 | 25.9 | 30.5 | 65 | 68 | 108 | 127 | 19.0 | 22.4 |

| 100 | 4 | 27.7 | 33.0 | 68 | 75 | 140 | 159 | 22.4 | 28.4 |

Weight Chart: ASME B16.11 Forged Pipe Cap

| NPS (Inch) | Class 3000 (kg) | Class 6000 (kg) |

|---|---|---|

| 1/2″ | 0.05 | 0.09 |

| 3/4″ | 0.08 | 0.15 |

| 1″ | 0.12 | 0.22 |

| 1 1/4″ | 0.18 | 0.32 |

| 1 1/2″ | 0.25 | 0.45 |

| 2″ | 0.42 | 0.75 |

| 2 1/2″ | 0.68 | 1.20 |

| 3″ | 0.95 | 1.65 |

| 4″ | 1.85 | 3.20 |

Socket Weld End Cap Tolerances as per ASME B16.11

| Dimension | Tolerance (mm) | Notes |

|---|---|---|

| Outside Diameter (OD) | ±1.5 mm | Applies to OD of cap |

| Socket Bore Diameter (ID) | ±0.5 mm | For socket weld type caps |

| Thread Dimensions | As per ASME B1.20.1 | For threaded caps |

| Wall Thickness | +1.0 mm / -0.5 mm | Ensures minimum strength |

| End-to-End Length | ±1.5 mm | Overall cap length |

| Socket Depth | ±0.5 mm | For socket weld caps |

| Squareness of End | ±0.5 mm | Measured against axis |

| Bevel Angle (if provided) | ±2° | For beveled end finish |

How are Socket Weld Caps different from Threaded Forged Caps in terms of application?

- Socket Weld Forged Caps:

- Designed for high-pressure pipelines (Class 3000#, 6000#, and 9000#).

- The cap is fitted onto the pipe end and fillet welded, which provides a

permanent and leak-proof joint. - Ideal for critical service applications such as

refineries, chemical plants, nuclear power plants, and offshore drilling platforms,

where safety and strength are more important than disassembly.

- Threaded Forged Caps:

- Manufactured with NPT or BSP threading as per ASME B1.20.1 standards.

- These allow easy installation and removal without welding,

making them suitable for maintenance-intensive systems. - Best for low-to-medium pressure systems, plumbing applications, and environments where

frequent disassembly or future modifications are expected.

Thus, the choice between socket weld and threaded caps depends on whether

the requirement is for a permanent, high-strength joint or a

removable connection.

How does Midland Forge and Fittings Pvt. Ltd. ensure quality in Forged Caps?

At Midland Forge and Fittings Pvt. Ltd., quality is our core focus. Our forged caps undergo strict inspection and testing procedures to meet international standards:

- Raw Material Inspection with 100% Positive Material Identification (PMI).

- Dimensional Accuracy Checks as per ASME B16.11 tolerances.

- Hydrostatic & Pneumatic Testing to ensure leak-proof performance.

- Non-Destructive Testing (NDT) including Ultrasonic, Magnetic Particle, and Dye Penetrant Testing for defect detection.

- Heat Treatment & Hardness Testing to maintain required mechanical properties.

- Certification & Compliance with ASME, ASTM, MSS SP-79, BS 3799, ISO, and API standards.

This rigorous quality process ensures that every forged cap delivered by Midland Forge provides safety, durability, and reliability in critical service conditions.

How do Forged Caps compare with Buttweld Pipe Caps?

Both forged caps and buttweld caps serve the same purpose— closing the pipe end—but their design and applications differ:

-

Forged Caps (ASME B16.11)

- Manufactured for small bore piping (½” to 4”).

- Suitable for high-pressure classes (2000#, 3000#, 6000#).

- Available in socket weld and threaded designs.

- Compact, stronger, and ideal for high-pressure compact systems.

-

Buttweld Caps (ASME B16.9)

- Manufactured for large-diameter pipes (up to 48”).

- Typically used in low-to-medium pressure applications.

- Welded directly to the pipe, providing a permanent closure.

- Common in pipeline projects, water supply systems, and petrochemical plants.

In short, forged caps = high-pressure, small size; buttweld caps = larger pipelines.