- Home

- Forged Fittings

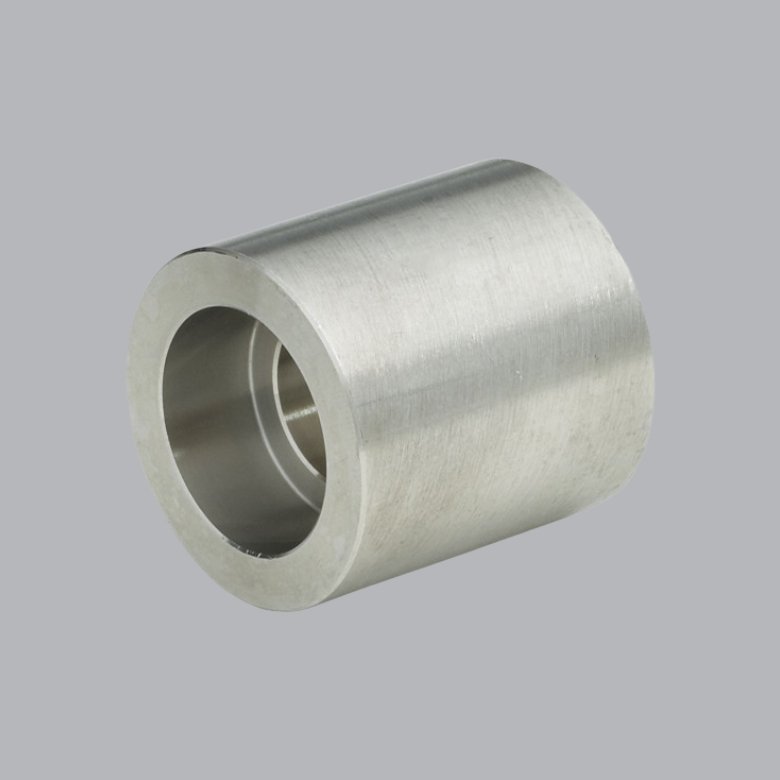

- Socket Weld & Threaded Coupling

Socket Weld & Threaded Coupling

Forged Coupling : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Premium ASME B16.11 Forged Socket Weld & Threaded Couplings – Full & Half | Trusted Manufacturer & Exporter in Stainless Steel, Carbon Steel, Alloy Steel & Nickel Alloys | USA, UAE & Germany

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a pioneer in delivering premium forged fittings for industrial piping systems. Combining state-of-the-art forging technology with stringent quality controls, we produce ASME B16.11 couplings,that stand up to extreme pressures and temperatures.

Our products, made from stainless steel, carbon steel, alloy steel, and nickel alloys, serve critical sectors including oil & gas, petrochemical, power, and chemical industries, reaching clients in USA, UAE, Germany, India, and Singapore. Designed for high-pressure and high-temperature applications, our forged couplings ensure durability, leak-proof performance, and long service life, meeting stringent international standards for industrial piping systems.

We offer a comprehensive range of full and half forged couplings designed for industrial pipelines. Full couplings provide seamless connections for extending pipe lines, while half couplings are ideal for branch connections and modifications. These couplings guarantee high strength, leak-proof performance, and dimensional accuracy, making them suitable for high-pressure and high-temperature applications.

Our Socket Weld and Threaded Couplings are engineered for durability and operational efficiency. Socket weld couplings deliver a permanent, high-strength joint for high-pressure industrial piping, whereas threaded couplings allow quick assembly and disassembly without welding. Available in sizes from ½” to 4” and pressure classes up to 6000, these couplings ensure safe, reliable, and long-lasting connections for industrial pipelines worldwide, meeting stringent international standards.

Forged Full Coupling Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Socket Weld Half Coupling– Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Types of ASME B16.11 Forged Coupling Fittings

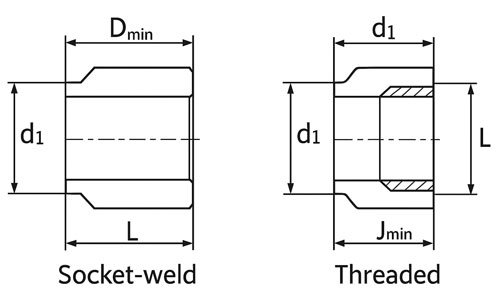

Dimensions of Socket Weld Forged Coupling – Full & Half (Class 3000# & 6000#)

| Nominal Size (NPS) | DN (mm) | Pressure Class | Wall Thickness (mm) |

Outside Diameter (mm) |

Socket Bore (mm) |

Length Full (mm) |

Length Half (mm) |

|---|---|---|---|---|---|---|---|

| ½” | 15 | 3000# | 3.2 | 21.3 | 14.3 | 50 | 25 |

| ½” | 15 | 6000# | 4.5 | 22.0 | 14.3 | 55 | 27 |

| ¾” | 20 | 3000# | 3.6 | 26.7 | 19.1 | 55 | 27 |

| ¾” | 20 | 6000# | 4.8 | 27.0 | 19.1 | 60 | 30 |

| 1″ | 25 | 3000# | 3.6 | 33.4 | 25.4 | 60 | 30 |

| 1″ | 25 | 6000# | 5.0 | 34.0 | 25.4 | 65 | 32 |

| 1½” | 40 | 3000# | 4.5 | 48.3 | 38.1 | 75 | 37 |

| 1½” | 40 | 6000# | 6.0 | 50.0 | 38.1 | 80 | 40 |

| 2″ | 50 | 3000# | 4.5 | 60.3 | 50.8 | 85 | 42 |

| 2″ | 50 | 6000# | 6.3 | 62.0 | 50.8 | 90 | 45 |

| 3″ | 80 | 3000# | 6.0 | 88.9 | 76.2 | 100 | 50 |

| 3″ | 80 | 6000# | 8.0 | 90.0 | 76.2 | 110 | 55 |

| 4″ | 100 | 3000# | 6.3 | 114.3 | 101.6 | 120 | 60 |

| 4″ | 100 | 6000# | 8.0 | 116.0 | 101.6 | 130 | 65 |

Dimensions of Threaded Forged Coupling – Full & Half (Class 3000# & 6000#)

| Nominal Size (NPS) | DN (mm) | Pressure Class | Thread Size | Outside Diameter (mm) | Length – Full (mm) | Length – Half (mm) |

|---|---|---|---|---|---|---|

| ½” | 15 | 3000# | ½” NPT | 27 | 45 | 22 |

| ½” | 15 | 6000# | ½” NPT | 30 | 50 | 25 |

| ¾” | 20 | 3000# | ¾” NPT | 33 | 50 | 25 |

| ¾” | 20 | 6000# | ¾” NPT | 36 | 55 | 27 |

| 1″ | 25 | 3000# | 1″ NPT | 41 | 55 | 27 |

| 1″ | 25 | 6000# | 1″ NPT | 45 | 60 | 30 |

| 1½” | 40 | 3000# | 1½” NPT | 55 | 70 | 35 |

| 1½” | 40 | 6000# | 1½” NPT | 60 | 75 | 38 |

| 2″ | 50 | 3000# | 2″ NPT | 70 | 80 | 40 |

| 2″ | 50 | 6000# | 2″ NPT | 75 | 85 | 42 |

| 3″ | 80 | 3000# | 3″ NPT | 95 | 95 | 48 |

| 3″ | 80 | 6000# | 3″ NPT | 100 | 105 | 52 |

| 4″ | 100 | 3000# | 4″ NPT | 120 | 110 | 55 |

| 4″ | 100 | 6000# | 4″ NPT | 125 | 120 | 60 |

Weight Chart: ASME B16.11 Couplings

| NPS (in) | DN (mm) | Class 3000# | Class 6000# |

|---|---|---|---|

| ½ | 15 | 0.12 / 0.06 | 0.18 / 0.09 |

| ¾ | 20 | 0.15 / 0.08 | 0.22 / 0.11 |

| 1 | 25 | 0.20 / 0.10 | 0.30 / 0.15 |

| 1¼ | 32 | 0.30 / 0.15 | 0.45 / 0.22 |

| 1½ | 40 | 0.38 / 0.19 | 0.57 / 0.28 |

| 2 | 50 | 0.55 / 0.28 | 0.83 / 0.42 |

| 2½ | 65 | 0.85 / 0.42 | 1.25 / 0.63 |

| 3 | 80 | 1.20 / 0.60 | 1.80 / 0.90 |

| 4 | 100 | 2.20 / 1.10 | 3.30 / 1.65 |

Socket Weld (SW) Coupling Tolerances as per ASME B16.11

| Parameter | Tolerance | Description |

|---|---|---|

| Outside Diameter (OD) | ±1.6 mm (for NPS ≤ 2”), ±2.4 mm (for NPS 2½”–6”) | Ensures proper alignment in the socket |

| Socket Bore Depth | ±0.8 mm | Controls proper insertion of pipe end |

| Socket Bore Diameter | ±0.3 mm | Ensures correct interference fit with pipe |

| Length (Overall) | ±1.5 mm | For assembly and alignment in piping |

| Wall Thickness | ±12.5% of nominal | Maintains pressure rating and mechanical strength |

Threaded (THD) Coupling Tolerances as per ASME B16.11

| Parameter | Tolerance | Description |

|---|---|---|

| Thread Outside Diameter | ±0.05 mm (1/8”–2”), ±0.10 mm (2½”–6”) | Ensures proper thread engagement |

| Thread Pitch & Angle | Per ASME B1.20.1 standard | Standard NPT thread specification |

| Length (Overall) | ±1.5 mm | Maintains proper joint length for piping assembly |

| Wall Thickness | ±12.5% of nominal | For pressure integrity |

What inspection methods are applied to ensure coupling quality?

- Dimensional Inspection: Using calipers, gauges, and micrometers

- Thread Verification: Thread plug gauges as per ASME B1.20.1

- Hydrostatic Testing: Pressure-tightness check at ≥1.5× rated pressure

- Material Verification: PMI, spectrography, or chemical analysis to confirm alloy

- Non-Destructive Testing (NDT): Optional dye penetrant or magnetic particle testing for critical pipelines

What is the importance of tolerances in forged couplings?

Tolerances ensure:

- Proper pipe insertion depth (socket weld)

- Leak-proof thread engagement (threaded)

- Interchangeability between fittings from different manufacturers

- Mechanical integrity under pressure and temperature cycles

Typical tolerances:

- OD: ±1.6–2.4 mm (depending on size)

- Socket Bore Diameter: ±0.3 mm

- Wall Thickness: ±12.5%

- Length: ±1.5 mm

How does material selection influence coupling performance?

- Carbon Steel: Economical, good for standard pressure and temperature applications

- Alloy Steel: Higher strength, suitable for elevated temperatures

- Stainless Steel: Corrosion-resistant, ideal for chemical or marine environments

- Nickel Alloys: Resistant to extreme corrosion, high temperatures, and special fluids