- Home

- Forged Fittings

- Socket Weld & Threaded Tee

Socket Weld & Threaded Tee

Forged Tee : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Top Manufacturers of ASME B16.11 Forged Tee Fittings – Equal & Unequal Socket Weld & Threaded Tee in Stainless Steel, Carbon Steel, Alloy Steel & High Nickel Alloys | USA, UK & Middle East

Best Export Prices: sales@midlandforgefittings.com

As a leading manufacturer, supplier, and exporter of ASME B16.11 Forged Tee fittings, we ensure precision engineering, strict quality control, and adherence to international standards. Backed by years of industry expertise, our company has built a strong reputation for delivering reliable and cost-effective piping solutions worldwide. With a customer-centric approach and a robust global network, we are committed to providing timely deliveries and unmatched service excellence.

Our forged tees are exported to USA, UK, Middle East, Europe, and Asia, catering to global clients across diverse sectors. With a strong focus on timely delivery, competitive pricing, and superior product quality, we have established ourselves as a trusted partner for forged pipe fittings worldwide.

We manufacture and supply Forged Tee fittings in a wide range of materials, including Stainless Steel, Carbon Steel, Alloy Steel, Duplex, Super Duplex, and High Nickel Alloys. With pressure ratings of 2000lb, 3000lb, 6000lb, and 9000lb, these fittings are suitable for critical industries such as oil & gas, petrochemical, power generation, and marine engineering. Whether it is a Socket Weld Forged Tee for a secure welded connection or a Threaded Forged Tee for easy assembly and disassembly, our products deliver reliability in every application.

Forged Tee fittings are crucial components in piping systems, designed to create a 90° branch connection from the main pipeline. Available in Equal Tee and Unequal (Reducing) Tee configurations, these fittings ensure smooth flow distribution without compromising system efficiency. Manufactured in compliance with ASME B16.11 standards, forged tees are offered in both Socket Weld and Threaded (Screwed) ends to meet diverse installation requirements. Their high mechanical strength, durability, and leak-proof performance make them ideal for high-pressure and high-temperature applications.

Forged Equal Tee Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Threaded Unequal Tee– Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Types of ASME B16.11 Forged Tee Fittings

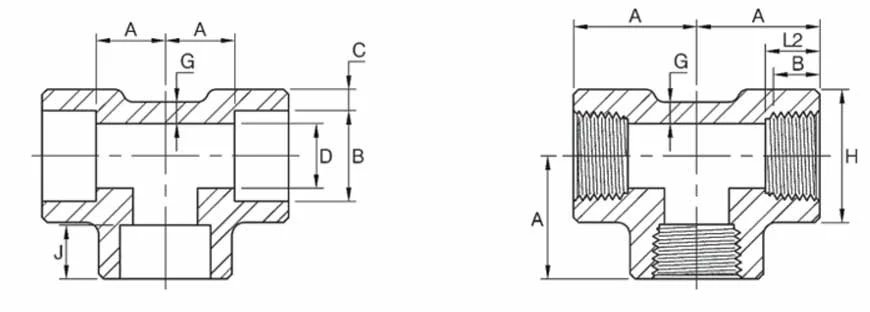

Dimensions of ASME B16.11 Socket Weld Tee(Class 3000, 6000, 9000)

Socket Welding Tee — 3000 lb

| DN | Nominal Pipe Size | B | C (Avg) | C (Min) | D | A | G (Min) | J (Min) |

|---|---|---|---|---|---|---|---|---|

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 6.9 | 11.0 | 2.41 | 9.5 |

| 8 | 1/4 | 14.2 | 3.78 | 3.30 | 9.3 | 11.0 | 3.02 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 3.50 | 12.6 | 13.5 | 3.20 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 15.8 | 15.5 | 3.73 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 4.27 | 21.0 | 19.0 | 3.91 | 12.5 |

| 25 | 1 | 33.9 | 5.69 | 4.98 | 26.7 | 22.5 | 4.55 | 12.5 |

| 32 | 1-1/4 | 42.7 | 6.07 | 5.28 | 35.1 | 27.0 | 4.85 | 12.5 |

| 40 | 1-1/2 | 48.8 | 6.35 | 5.54 | 40.9 | 32.0 | 5.08 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 52.5 | 38.0 | 5.54 | 16.0 |

| 65 | 2-1/2 | 73.9 | 8.76 | 7.87 | 62.7 | 41.0 | 7.01 | 16.0 |

| 80 | 3 | 89.8 | 9.52 | 8.30 | 78.0 | 57.0 | 7.62 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.35 | 102.3 | 66.5 | 8.56 | 19.0 |

Socket Welding Tee — 6000 lb

| DN | Nominal Pipe Size | B | C (Avg) | C (Min) | D | A | G (Min) | J (Min) |

|---|---|---|---|---|---|---|---|---|

| 6 | 1/8 | 10.8 | 3.96 | 3.43 | 4.0 | 11.0 | 3.15 | 9.5 |

| 8 | 1/4 | 14.2 | 4.60 | 4.01 | 6.4 | 13.5 | 3.68 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 9.2 | 15.5 | 4.01 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 11.8 | 19.0 | 4.78 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 15.6 | 22.5 | 5.56 | 12.5 |

| 25 | 1 | 33.9 | 7.92 | 6.93 | 20.7 | 27.0 | 6.35 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 29.5 | 32.0 | 6.35 | 12.5 |

| 40 | 1-1/2 | 48.8 | 8.92 | 7.80 | 34.0 | 38.0 | 7.14 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 42.9 | 41.0 | 8.74 | 16.0 |

Socket Welding Tee — 9000 lb

| DN | Nominal Pipe Size | B | C (Avg) | C (Min) | D | A | G (Min) | J (Min) |

|---|---|---|---|---|---|---|---|---|

| 15 | 1/2 | 21.8 | 9.35 | 8.18 | 6.4 | 25.5 | 7.47 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 11.1 | 28.5 | 7.82 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 15.2 | 32.0 | 9.09 | 12.5 |

| 32 | 1-1/4 | 42.7 | 12.14 | 10.62 | 22.8 | 35.0 | 9.70 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 28.0 | 38.0 | 10.15 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.12 | 38.2 | 54.0 | 11.07 | 16.0 |

Dimensions of ASME B16.11 Threaded Tee(Class 2000, 3000, 6000)

Threaded Tee Fittings – 2000Lb

| DN | Norm Pipe Size | Length of Thread | A | G (Min) | H | |

|---|---|---|---|---|---|---|

| B | L2 | |||||

| 6 | 1/8 | 6.4 | 6.7 | 21 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 21 | 3.18 | 22 |

| 10 | 3/8 | 9.1 | 10.4 | 25 | 3.18 | 25 |

| 15 | 1/2 | 10.9 | 13.6 | 28 | 3.18 | 33 |

| 20 | 3/4 | 12.7 | 13.9 | 33 | 3.18 | 38 |

| 25 | 1 | 14.7 | 17.3 | 38 | 3.68 | 46 |

| 32 | 1-1/4 | 17.0 | 18.0 | 44 | 3.89 | 56 |

| 40 | 1-1/2 | 17.8 | 18.4 | 51 | 4.01 | 62 |

| 50 | 2 | 19.0 | 19.2 | 60 | 4.27 | 75 |

| 65 | 2-1/2 | 23.6 | 28.9 | 76 | 5.61 | 92 |

| 80 | 3 | 25.9 | 30.5 | 86 | 5.99 | 109 |

| 100 | 4 | 27.7 | 33.0 | 106 | 6.55 | 146 |

Threaded Tee Fittings – 3000Lb

| DN | Norm Pipe Size | Length of Thread | A | G (Min) | H | |

|---|---|---|---|---|---|---|

| B | L2 | |||||

| 5 | 1/8 | 6.4 | 6.7 | 21 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 25 | 3.30 | 25 |

| 10 | 3/8 | 9.1 | 10.4 | 28 | 3.51 | 33 |

| 15 | 1/2 | 10.9 | 13.6 | 33 | 4.09 | 38 |

| 20 | 3/4 | 12.7 | 13.9 | 38 | 4.32 | 46 |

| 25 | 1 | 14.7 | 17.3 | 44 | 4.98 | 56 |

| 32 | 1-1/4 | 17.0 | 18.0 | 51 | 5.28 | 62 |

| 40 | 1-1/2 | 17.8 | 18.4 | 60 | 5.56 | 75 |

| 50 | 2 | 19.0 | 19.2 | 64 | 7.14 | 84 |

| 65 | 2-1/2 | 23.6 | 28.9 | 83 | 7.65 | 102 |

| 80 | 3 | 25.9 | 30.5 | 95 | 8.84 | 121 |

| 100 | 4 | 27.7 | 33.0 | 114 | 11.18 | 152 |

Threaded Tee Fittings – 6000Lb

| DN | Norm Pipe Size | Length of Thread | A | G (Min) | H | |

|---|---|---|---|---|---|---|

| B | L2 | |||||

| 6 | 1/8 | 6.4 | 6.7 | 25 | 6.35 | 25 |

| 8 | 1/4 | 8.1 | 10.2 | 28 | 6.60 | 33 |

| 10 | 3/8 | 9.1 | 10.4 | 33 | 6.98 | 38 |

| 15 | 1/2 | 10.9 | 13.6 | 38 | 8.15 | 46 |

| 20 | 3/4 | 12.7 | 13.9 | 44 | 8.53 | 56 |

| 25 | 1 | 14.7 | 17.3 | 51 | 9.93 | 62 |

| 32 | 1-1/4 | 17.0 | 18.0 | 60 | 10.59 | 75 |

| 40 | 1-1/2 | 17.8 | 18.4 | 64 | 11.07 | 84 |

| 50 | 2 | 19.0 | 19.2 | 83 | 12.09 | 102 |

| 65 | 2-1/2 | 23.6 | 28.9 | 95 | 15.29 | 121 |

| 80 | 3 | 25.9 | 30.5 | 106 | 16.64 | 146 |

| 100 | 4 | 27.7 | 33.0 | 114 | 18.67 | 152 |

Weight Chart: ASME B16.11 Forged Tee (Class 2000, 3000, 6000)

| Class 2000 | Nominal Pipe Size | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.740 | 1.058 | 1.375 | 1.740 | 2.883 | 7.750 | 11.313 | 19.125 | |

| Class 3000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.250 | 0.290 | 0.500 | 0.750 | 1.188 | 1.988 | 2.235 | 3.000 | 4.930 | 7.375 | 13.588 | 19.063 | |

| Class 6000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.250 | 0.640 | 0.500 | 1.438 | 2.188 | 2.785 | 4.688 | 5.750 | 9.500 | 15.000 | 30.563 | – | |

Forged Tee Tolerances as per ASME B16.11

| Parameter | Tolerance (±) |

|---|---|

| Center-to-End Dimension (A, B, C) | ± 1.5 mm (1/16 in) |

| Overall Length | ± 1.5 mm (1/16 in) |

| Outside Diameter at End (D) | ± 1.5 mm (1/16 in) |

| Wall Thickness (T) | Not less than specified (no negative tolerance allowed) |

| Socket Bore Diameter (for Socket Weld) | ± 0.13 mm (± 0.005 in) |

| Thread Dimensions (for Threaded Tees) | As per ASME B1.20.1 (NPT Taper Threads) |

| Out-of-Roundness (OD) | ≤ 1% of OD |

| Center-to-End Squareness (misalignment) | ≤ 0.8 mm (1/32 in) |

| Angularity (between outlets) | ± 0.5° |

| Alignment of Threads (Threaded Ends) | ± 1° |

What is the main difference between a Socket Weld Tee and a Threaded Tee?

-

A Socket Weld Tee has a recessed area (socket) where the pipe is inserted. After insertion, a fillet weld is applied around the joint. This welding method creates a strong, permanent, and leak-proof connection, making it highly reliable in high-pressure and high-temperature systems.

-

A Threaded Tee, on the other hand, has internal screw threads (NPT or BSP) that allow pipes to be directly connected without welding. Since no welding is involved, installation is quicker and easier, but the joint is not as strong as a welded one. Threaded tees are best suited for low-pressure, non-critical, or temporary piping systems.

Are there any limitations in using Socket Weld Tees and Threaded Tees?

-

Socket Weld Tees:

- Generally limited to pipe sizes up to NPS 4″.

- Not suitable for applications requiring dismantling or adjustments, since removal requires cutting and re-welding.

- Welding may introduce stress and requires skilled labor.

-

Threaded Tees:

- Limited to low and moderate pressures only (usually up to Class 3000).

- Not suitable for high-vibration systems, as threads can loosen over time.

- Threading reduces wall thickness at the connection, which weakens the joint compared to welded fittings.

How do tolerances differ for Socket Weld and Threaded Tees?

ASME B16.11 specifies strict dimensional tolerances for both types:

- Socket Weld Tees → Controlled tolerances in socket bore, wall thickness, and center-to-end dimensions to ensure that pipes fit properly and welds are strong. Misalignment tolerance is also specified to avoid stresses in the welded joint.

- Threaded Tees → Require precise thread cutting as per ASME B1.20.1 (NPT Taper Threads) or BSP standards. Tolerances for thread depth, pitch, and engagement are critical for ensuring leak-free sealing when a thread sealant (e.g., PTFE tape or compound) is used.